Deliverables WP4

DELIVERABLE 4.1: ‘Report on the environmental profile of alkali activated materials for structural applications’

- Introduction

The study aims to assess the environmental impacts of the alkali activation process applied to the recycling of industrial waste. The processes developed within the project were analyzed to identify the most environmentally advantageous options. The environmental performance of the processes was evaluated by applying the Life Cycle Assessment (LCA) methodology. LCA studies were carried out through 4 phases:

- goal and scope definition;

- life cycle inventory analysis (LCI);

- life cycle impacts analysis (LCIA);

- life cycle interpretation.

1.1 Goal and scope definition

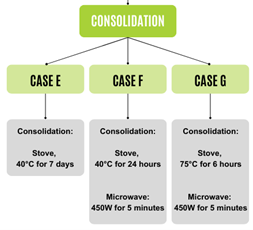

The life cycle assessment methodology is adopted to evaluate the environmental impacts of the innovative alkali activation processes to obtain solid glass. A total of 3 Life Cycle Assessment (LCA) studies is conducted to verify which is the preferable consolidation process from an environmental point of view. Figure 1 summarizes the main differences between the cases considered. For all the processes analyzed, the functional unit is equal to 1kg of product intended to be used as an insulating material in the construction sector.

Fig.1 Summary of the main differences between the compared cases.

1.2 System boundaries

The system boundaries refer to a gate-to-gate approach from the industrial glass waste to the final product (glass foam or glass solid). The upstream and downstream phases are excluded because the aim is to measure the impact of the processes. Primary data is collected directly in the datasheets provided to the project partners. Spreadsheets allow the analysis of energy consumption and necessary resources by verifying mass and energy balances. The primary data used for the analysis are provided by partners and are referred to as operating data. Background inventory data referring to raw materials, transport, and electricity are sourced from the commercial database Ecoinvent. All the information is related to the functional unit defined in goal and scope phase. The collected data, whether measured, calculated, or estimated, are utilized to quantify the inputs and outputs of a unit process.

1.3 Life cycle impact assessment and interpretation of results

The system’s inputs and outputs are introduced in SimaPro 10.1.0.4 and converted into potential environmental impacts through the ReCiPe 2016 v1.1 midpoint, Egalitarian perspective. During the interpretation of the data, the results are deepened through a sensitivity analysis and an uncertainty analysis.

- Results

2.1 Life cycle impact assessment results

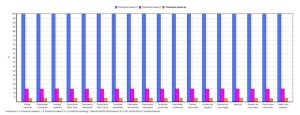

The comparison between the cases E, F and G through the ReCiPe method is reported in Fig. 2 (characterization and normalization). It is possible to observe the impact of each phase of the analyzed process. Case E has the worst environmental performance for all impact categories analyzed. While case G is the best for all the impact categories. The normalization shows that the greatest contribution is in the human toxicity (non-carcinogenic) impact category because it is the one most affected by energy consumption.

Fig.2 LCIA calculated by ReCiPe for CASE E, F and G: Characterization and Normalization

2.2 Interpretation of results

Considering that the impacts are mainly due to energy consumption, we want to investigate how environmental profiles change when the energy source varies. The sensitivity analysis was conducted by replacing the Italian energy mix with solar energy via photovoltaic panels. Assuming that the photovoltaic system is already installed, the impacts are reduced for cases E, F and G. The uncertainty analysis is carried out to assess how much the results are affected by input data uncertainty. Even when comparing the best-case and worst-case scenarios for both processes, the result remains the same. For solids, case G remains the best choice. Monte Carlo simulations (1000 iterations) show that in 100% options G is better than the other alternatives. However, the water consumption category is most affected by uncertainty and only in this case the result is not overwhelming.

- Conclusions

The main results are summarized below:

- Process G performs better than processes E and F from an environmental perspective;

- For all processes, the greatest impacts are due to energy consumption;

- The most relevant impact category is Human Toxicity (Non-carcinogenic);

- When using photovoltaic energy, the impacts are reduced for most of the categories;

- Despite the uncertainty associated with the data, the results are confirmed.

Overall, it can be highlighted that even during the design and laboratory testing phases, it is possible to intervene in the process to study and improve environmental performance.

DELIVERABLE 4.2: ‘Report on the environmental profile of alkali activated materials for water treatment, with special focus on the impact of functional additives’

- Introduction

The study aims to assess the environmental impacts of the alkali activation process applied to the recycling of industrial waste. The processes developed within the project were analyzed to identify the most environmentally advantageous options. The environmental performance of the processes was evaluated by applying the Life Cycle Assessment (LCA) methodology. LCA studies were carried out through 4 phases:

- goal and scope definition;

- life cycle inventory analysis (LCI);

- life cycle impacts analysis (LCIA);

- life cycle interpretation.

1.1 Goal and scope definition

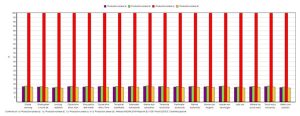

The life cycle assessment methodology is adopted to evaluate the environmental impacts of the innovative alkali activation processes to obtain glass foam. A total of 4 Life Cycle Assessment (LCA) studies is conducted to verify which is the preferable foaming process from an environmental point of view. Figure 1 summarizes the main differences between the cases considered. For all the processes analyzed, the functional unit is equal to 1kg of product intended to be used as an insulating material in the construction sector.

Fig.1 Summary of the main differences between the compared cases.

1.2 System boundaries

The system boundaries refer to a gate-to-gate approach from the industrial glass waste to the final product (glass foam or glass solid). The upstream and downstream phases are excluded because the aim is to measure the impact of the processes

1.3 Life cycle inventory

Primary data is collected directly in the datasheets provided to the project partners. Spreadsheets allow the analysis of energy consumption and necessary resources by verifying mass and energy balances. The primary data used for the analysis are provided by partners and are referred to as operating data. Background inventory data referring to raw materials, transport, and electricity are sourced from the commercial database Ecoinvent. All the information is related to the functional unit defined in goal and scope phase. The collected data, whether measured, calculated, or estimated, are utilized to quantify the inputs and outputs of a unit process.

1.4 Life cycle impact assessment and interpretation of results

The system’s inputs and outputs are introduced in SimaPro 10.1.0.4 and converted into potential environmental impacts through the ReCiPe 2016 v1.1 midpoint, Egalitarian perspective. During the interpretation of the data, the results are deepened through a sensitivity analysis and an uncertainty analysis.

- Results

2.1 Life cycle impact assessment results

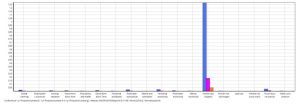

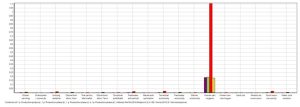

The comparison between cases A, B, C and D through the ReCiPe method is reported in Fig. 2 (characterization and normalization). It is possible to observe the impact of each phase of the glass foam process. Case C has the worst environmental performance for all impact categories analyzed. The other processes have similar environmental characteristics, but case D is the best in all impact categories. In general, the greatest contribution is in the human toxicity (non-carcinogenic) impact category because it is the one most affected by energy consumption.

Fig.2 LCIA calculated by ReCiPe for CASE A, B, C and D: Characterization and Normalization

2.2 Interpretation of results

Considering that the impacts are mainly due to energy consumption, we want to investigate how environmental profiles change when the energy source varies. The sensitivity analysis was conducted by replacing the Italian energy mix with solar energy via photovoltaic panels. Assuming that the photovoltaic system is already installed, the impacts are reduced for cases A, B, C and D. The uncertainty analysis is carried out to assess how much the results are affected by input data uncertainty. Even when comparing the best-case and worst-case scenarios for both processes, the result remains the same. For foams, case D is consistently preferred. Monte Carlo simulations (1000 iterations) show that in 100% options D is better than the other alternatives. However, the water consumption category is most affected by uncertainty and only in this case the result is not overwhelming.

- Conclusions

The main results are summarized below:

- Process D performs better than processes A, B, and C from an environmental perspective;

- For all processes, the greatest impacts are due to energy consumption;

- The most relevant impact category is Human Toxicity (Non-carcinogenic);

- When using photovoltaic energy, the impacts are reduced for most of the categories;

- Despite the uncertainty associated with the data, the results are confirmed.

Overall, it can be highlighted that even during the design and laboratory testing phases, it is possible to intervene in the process to study and improve environmental performance.

DELIVERABLE 4.3: ‘Report on potential for photocatalytic destruction of organics and disinfection’

As a strategy to address clean water scarcity, the development of inexpensive and eco-friendly materials for wastewater treatment is essential. Our approach focuses on minimizing the use of virgin raw materials by implementing up-cycling strategies. In particular, we produced novel magnetic foams derived from soda-lime glass waste fractions and volcanic ash from natural eruptions through an alkali-activation process. Magnetic properties were imparted by incorporating Fe3O4 magnetite nanoparticles coated with a silica layer to improve their interaction with the matrix.

The resulting materials have attracted considerable interest for pollutant removal for several reasons:

- Their highly porous structure enhances removal efficiency by providing abundant active adsorption sites and facilitating pollutant diffusion through the interconnected pore network.

- The use of magnetic fillers enables easy recovery of the foams from treated water using simple magnets, eliminating the need for filtration or centrifugation, which are more complex and costly.

- The inherent Fe2O3 content in volcanic ash allows the foams to act as effective photocatalytic supports, generating a combined adsorption/photocatalytic effect during pollutant removal.

To evaluate both adsorption and visible-light photocatalytic performance, methylene blue was selected as a model pollutant and a dedicated test setup was developed. Foams containing 5 and 10 wt% magnetic nanoparticles were compared to analogous foams prepared without nanoparticles. Higher nanoparticle loadings were avoided to prevent excessive pore blockage, saturation of active sites, and enhanced electron–hole recombination.

Adsorption experiments carried out in the dark, thus excluding any light-driven contributions, revealed that, despite a gradual decrease in porosity with increasing nanoparticle content, adsorption efficiency increased up to 94% due to the additional contribution of the magnetic nanoparticles. The best performance was observed under visible light irradiation. Thanks to the presence of Fe2O3 in the raw materials and the additional iron provided by the nanoparticles, a photo-Fenton-like mechanism was activated, enabling an almost complete removal of the model pollutant.

These promising results encouraged us to further advance this research by exploring the optimization of magnetic foam composition and the incorporation of additional photocatalysts.

DELIVERABLE 4.4: ‘Report on second generation alkali activated materials’

According to schedules activities, particular attention was dedicated to ‘end-of-life’ options for the obtained materials. To enhance the circularity of the approach, optimized products were reduced to fine powders and tested for further activation. Opal glass dense products were ground again, and the powders were reactivated with NaOH 1.25 M solution and with distilled water. The slurries underwent consolidation as usual (stove and microwave treatment) and then characterized. Consolidation occurs both in the presence of water and in the presence of highly diluted alkaline solution. Reactivation with NaOH appears more resistant and better withstands boiling tests while samples reactivated with water tend to partially disintegrate into boiling water. The further activation of the glass powders was also highlighted by the XRD spectra of the reactivated samples in which the formation of hydrated carbonates and additional gel phase is clearly noted even in the presence of water alone.