MODEL-BASED CONTROL OF PHOTOBIOREACTORS

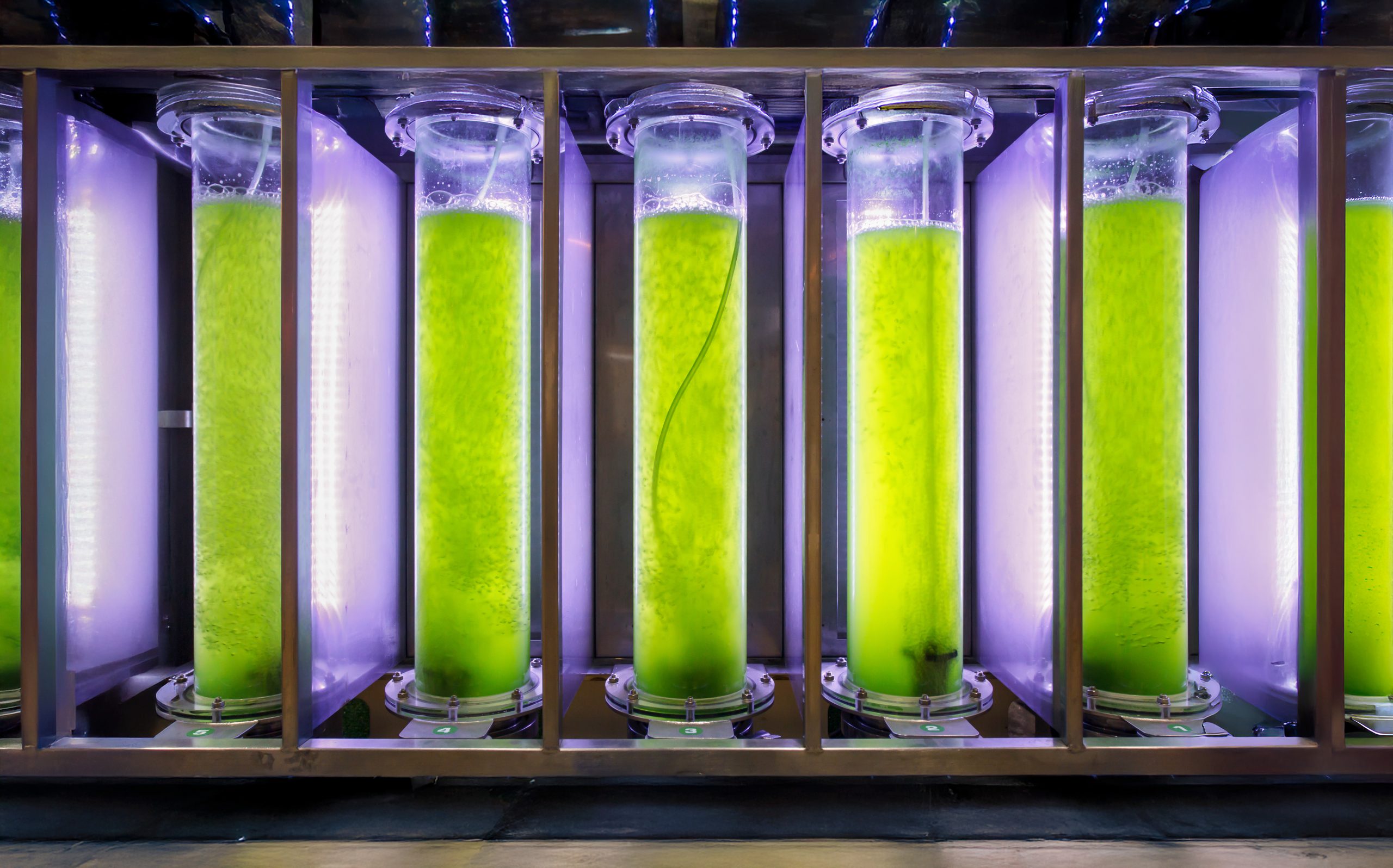

Photobioreactors are closed systems designed to grow photosynthetic organisms like microalgae under controlled conditions. They provide light, carbon dioxide, nutrients, and mixing to optimize growth while protecting the culture from contamination and environmental fluctuations. This is particularly helpful, as microalgae growth depends on a delicate balance of these parameters. Howevers, traditional control methods react to changes only after they occur. By adopting model predictive control (MPC) strategies, we can anticipate issues and prevent them before they impact growth—keeping algae cultures in their optimal state for maximum productivity. MPC can also be used to determine the exact lighting pattern that maximizes photosynthesis while minimizing energy usage—a significant cost-saving opportunity.

MPC transforms microalgae operations, making them more efficient, more profitable, and more scalable. This makes it a transformative tool, particularly as the algae industry expands into food, fuel, pharma, and climate tech markets.

STRAIN SELECTION AND GENETIC ENGINEERING

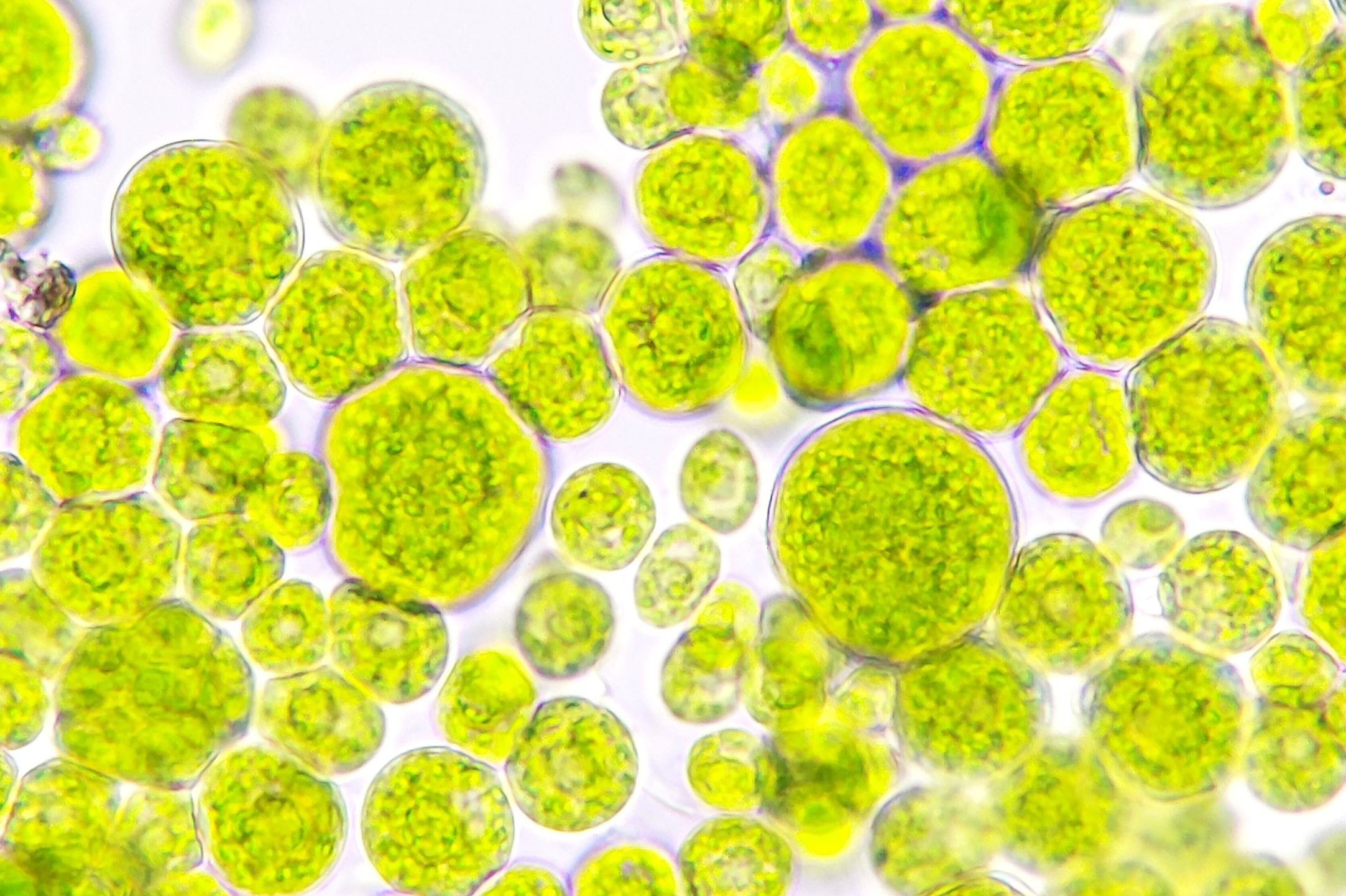

One of the major challenges in the industrial cultivation of microalgae is the limited availability of CO₂. As photosynthetic organisms, microalgae rely on CO₂ as a key carbon source for the synthesis of macromolecules required for growth. However, the enzyme responsible for CO₂ fixation—RuBisCO—is inherently inefficient, as it can also bind to oxygen, leading to the production of toxic by-products.

The bioengineering aspect of the project focuses on improving the metabolic pathway responsible for detoxifying these harmful by-products. An alternative and more efficient pathway, originally found in proteobacteria, is being introduced into Nannochloropsis strains. This modification is expected to enhance cellular growth and productivity. The engineered strains will be cultivated under industrial-like conditions to evaluate the practical benefits of the genetic enhancement for large-scale applications.

DEVELOPMENT OF GROWTH MODELS

What hinders the industrial use of microalgae is their limited photosynthetic efficiency, which refers to their ability to convert light energy into chemical energy. In fact, the maximum efficiency achieved at the laboratory level is around 5%, while at the industrial level it is only about 2%. These values are significantly lower than the theoretical maximum, which is estimated to be around 12%. This results in high operational costs that, in some cases, can only be offset by the high added value of the final product.

Therefore, the development of a digital model of microalgae growth would make it possible to identify the optimal operating conditions in order to improve photosynthetic efficiency and support the development of industrial processes involving microalgae.

EFFECT OF ARTIFICIAL PULSED LIGHT ON GROWTH

Pulsed light has recently emerged as a potentially effective light regime for microalgal cultivation, providing several benefits over continuous light, such as energy saving, cost reduction, and increased photosynthetic efficiency. Additionally, it is known that the enzymes and proteins involved in photosynthesis are highly temperature-sensitive. Accordingly, the purpose of this project is to explore the combined effects of pulsed light and temperature on Acutodesmus obliquus in order to investigate the optimal conditions that maximize photosynthetic efficiency and growth. Interesting results were observed by conducting pulsed light respirometric tests at different temperatures, focusing first on the effect of dark time and subsequently on that of light time. Future experiments will therefore be conducted directly on the reactors in continuous mode with the intent of validating some of the preliminary results obtained with respirometric tests.