GLASS_Trea.S.U.Res project

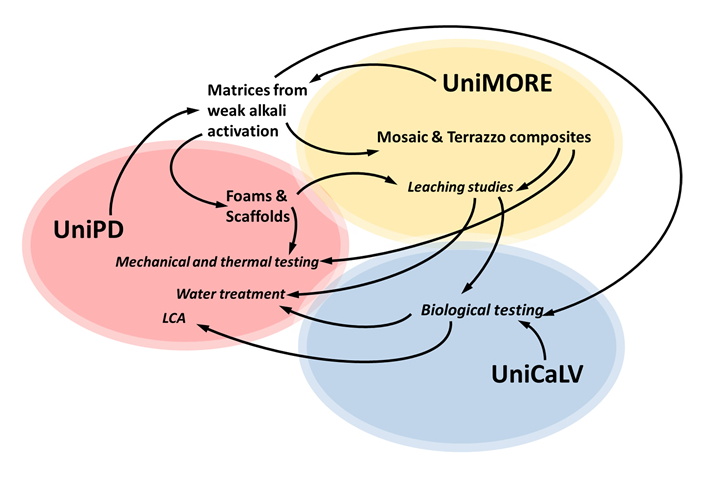

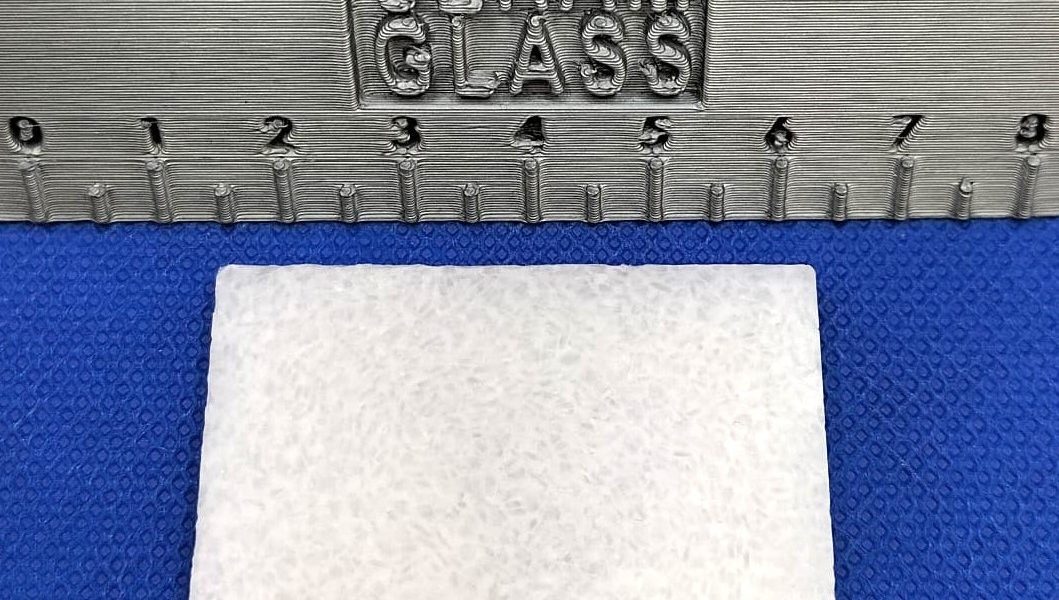

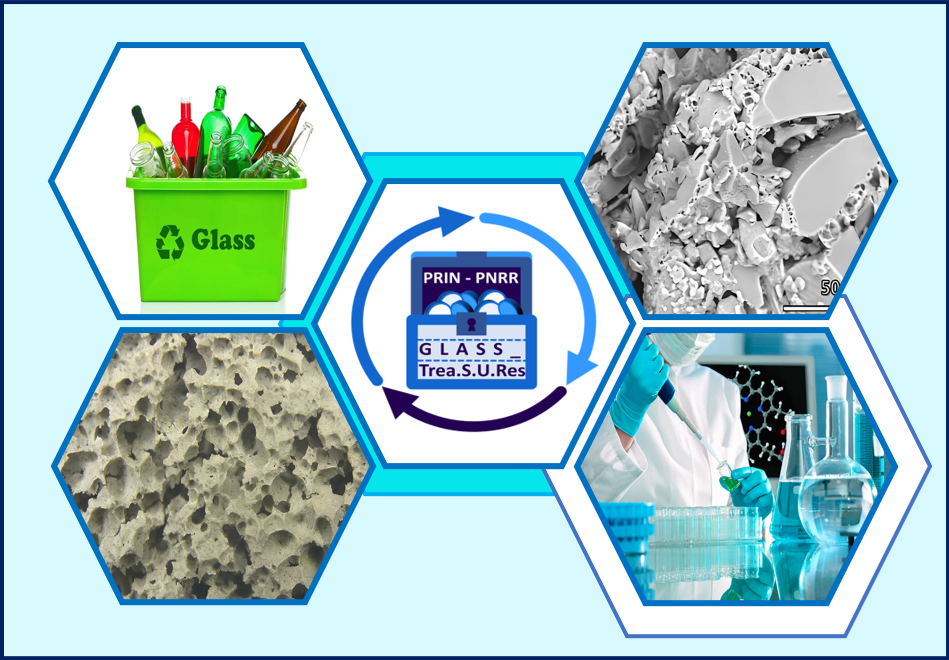

The development of valuable new products (‘up-cycling’) is fundamental for avoiding any landfilling of the glass fractions (‘waste glasses’) which are normally unemployed, e.g. due to polymer and metal contaminations [1]. The balance between inputs and outputs of supplementary materials, energy and emissions, however, remains challenging. This projects aims at defining new structural and functional materials by alkali activation treatments at nearly room temperature, triggered by the same chemical composition of waste glasses, possibly mixed with other inorganic (and mainly glassy) residues. Alkali activation corresponds to the extensive dissolution of silicate and alumino-silicate powders, suspended in concentrated aqueous solutions of alkali hydroxides, silicates and aluminates. With a proper balance among constituent oxides (SiO2, Al2O3, alkali oxides), condensation reactions of the dissolution products determine, at nearly room temperature, stable gels, featuring a three-dimensional ‘zeolite-like’ network structure (resulting from the bridging of SiO4 and AlO4 units, the latter being stabilized by alkali ions in the surroundings). In this framework, waste glasses have been widely considered, as providers of SiO2 and alkali oxides, after dissolution in highly concentrated attacking solutions [2]. The present project, according to very recent findings [3], aims at developing far more sustainable alkali-activated materials, operating with diluted alkali hydroxide solutions (molarity not exceeding 3M). Zeolite-gels may result from the surface activation of fine powders of relatively Al2O3-rich waste glasses or blends of waste glass with other Al2O3-rich residues, such as volcanic materials [4,5]. A full circularity can be achieved only with a clear identification of useful target products [1]. As a further proof of sustainability, the present project aims at defining both dense and porous structural components, to replace building products, such as clay bricks, lightweight concrete, glass and ceramic foams, already obtained by energy- and material-demanding processes. Dense products will imply the adoption of glass cullet or other inorganic residues also in form of coarse powders, bound by thin layers of matrix resulting from fine powders. In parallel, cellular products will rely on the gas incorporation in matrices at the early stages of gelation, by intensive mechanical stirring and/or decomposition of foaming agents, possibly supported by surfactants. The new products will undergo an extensive environmental impact analysis, in form of leaching (to assess the effective permanent stabilization of pollutants, from cullet and/or other residues) and life cycle sustainability assessment. Finally, cellular materials, not only resulting from foaming, but also from the application of modern additive manufacturing technologies, will be considered for their potential in water remediation, in analogy with several alkali-activated systems [6,7].

1. Rincon et al., J. Chem. Tech. Biotech. 91 (2016) 1946-61 – 10.1002/jctb.4982

2. Toniolo et al., Constr. Build. Mater. 188 (2018) 1077-1084 – 10.1016/j.conbuildmat.2018.08.096

3. Mehta et al., Materials 15 (2022) 3784 – 10.3390/ma15113784

4. Mahmoud et al., Materials 15 (2022) 6823 – 10.3390/ma15196823

5. Bernardo et al., Constr. Build. Mater. 359 (2022) 129540 – 10.1016/j.conbuildmat.2022.129540

6. Youmoue et al., SN Appl. Sci. 2 (2020) 642 – 10.1007/s42452-020-2388-x

7. Luukkonen et al., Sci. Rep. 10 (2020) 7233 – 10.1038/s41598-020-64228-5